What is water jet laser dicing?

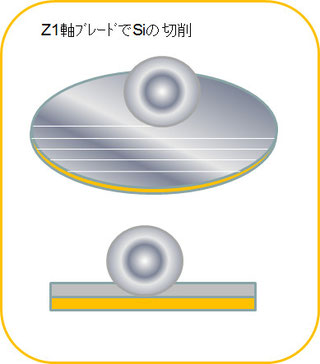

Laser light is introduced into the water jet, and laser light is guided to the surface of the workpiece by utilizing the total reflection phenomenon at the interface. By doing so, there is the merit that it is possible to change the processing width by suppressing the thermal effect, removing foreign matter, changing the nozzle. Furthermore, by making the Z axis two axes and hybridizing with the blade, two-step machining of dicing backside metal film with laser is possible with one chuck.

Characteristics of water jet laser

- Since the laser is reflected at the interface of water and irradiated to the substrate, focusing is unnecessary.

- Cut width can be changed simply by changing nozzle diameter.

- Heat effect can be suppressed by water cooling effect.

Processing example (comparison with blade dicing)

Comparison of backside metal film state.

Blade only

Water jet laser