Film-formation-processing

We propose optimum method as a film forming method from various PVD such as sputtering, vacuum evaporation, ion plating, CVD typified by TEOS film.

Particularly sputtering, we have abundant targets, 2 targets at same time, 3 layers deposited within the same vacuum. Equipment can be selected according to your needs from small size to large size. (Target list is here)

Work size can be selected from small piece up to 12 inch.

Various blanket wafers can be made for CMP processing.

(Thin film, Cu film, PE-TEOS, PE-SiN etc.)

About sputtering

- The energy of the particles forming the film is large and it is possible to form a film with strong adhesion.

- Film formation is possible while maintaining composition ratio of alloys and compounds almost.

- Film formation is possible even with a high melting point target.

- High precision film thickness control is possible with time control only.

- Film forming of oxide and nitride by reactive gas is possible.

- Heating substrate is possible. (300℃)

- Film forming on film is possible.

- Abundant targets (Target list is here)

Please also see the page “About sputtering” explained about sputtering.

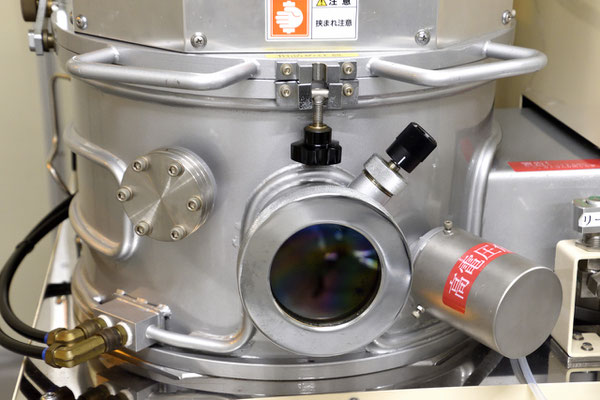

About ion beam sputtering

- Since the target is irradiated with ions generated by the ion gun, it is not necessary to make plasma by discharge, and film forming in high vacuum is possible (impurities do not mix).

- Ion sources are independent and condition setting is easy.

- Regardless of the material of the target.

- It is possible to form ultra thin films.

About vacuum vapor deposition / ion plating

- Fast deposition rate.

- No sample damage due to plasma.

- Film forming on film possible.

- Can handle thick film.

- Low film stress.

- Ideal for lift-off film deposition.

About CVD

- Good coverage.

- TEOS can be used for small piece.

- TEOS thick film can be formed by PE-CVD (up to about 20um)

- Here is a list of films that can be formed.